A printed label is a key component of any application in which items need to be identified quickly and easily. Though printed labels may seem unsophisticated at first, their benefits are very powerful, assuming they are created properly. Whether you are making labels for shipments, for a business asset, or for products, a barcoded label is a reliable tool to help manage any tracking system.

All label printing systems consist of three main parts: the printer, media (labels, ribbons) and design software. Depending on your business needs, there are solutions to support low volume office printing to full scale industrial and mobile applications. Ensuring these components are properly matched to each other and to your application requirements is essential to getting the greatest return on your system.

What are the Key Benefits of Barcode Label Printing?

Millions of companies around the world rely on barcode printing to improve data management and accessibility, reduce costs and increase productivity. This innovative and easy-to-implement technology allows companies in virtually any industry to benefit using labels.

- Accuracy – Improve data accuracy to over 99% by labeling assets and inventory with barcodes and

automating data collection, removing virtually any room for errors. - Efficiency – Increase efficiency (work faster and free up employees’ time) by converting manual

tracking tasks into electronic, real-time processes using barcode labels. - Consistency – Ensure consistent and predictable operations for enhanced product quality by combining data management functions and preventing bottlenecks at data entry stations.

What is Barcode Label Printing?

A common debate for companies considering barcode printing is the value between using pre-printed labels from a third-party versus on-demand printing with their own barcoding system. Pre-printed labels are useful when your application requires only a few identical labels, often with multiple colors or graphics. However, companies that start with pre-printed labels quickly discover their limitations. Besides restricted flexibility, the use of pre-printed labels prevents companies from including variable customer data or combinations of text and barcode information. Most companies find the financial commitment of on-demand barcodes worth the initial investment because of the added value from printing customized information on each label.

Most barcode label printing is done with thermal based printers as opposed to laser or ink jet devices. Outside of the lower cost of ownership when compared to the other technologies, thermal printers also offer true one-off on-demand printing that is precise for easy scanning. With the barcode label being such an integral part of any system you want to ensure it is clearly printed with no bleeding to ensure even the simplest scanner can get good reads.

There are 2 types of thermal printing and each one offers specific benefits depending on the requirements of your application.

- Direct Thermal Printing

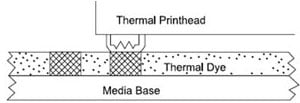

Direct Thermal Printing Direct thermal printing utilizes heat-sensitive media that blackens as it passes under the printhead. Because they print without a ribbon, direct thermal printers are noted for their simplicity. Direct thermal printed labels typically have a considerable shelf life but are not well suited for environments that expose them to heat, long periods of direct sunlight or abrasion. Because of this, thermal labels, tags or ticket stock are often top coated to resist these elements. Direct thermal printing produces sharp print quality with good scan ability using only one consumable. For any short term labeling application, like shipping labels, Direct Thermal is the most efficient print method. - Thermal Transfer Printing

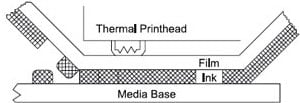

Thermal Transfer Printing Thermal transfer printed labels are easily identified by their crisp, often glossy printed surface. This clarity is achieved by using a thin ribbon roll that is heated by the printhead and melts onto the label to form the image. Thermal transfer technology is not only impervious to heat and moisture, but the image cannot be rubbed off, making the printed labels the most durable, long-lived available. Since the color and density is determined by the ribbon and the printer’s resolution, this method produces consistent, reliable printing on every label. Thermal Transfer printing also supports label materials beyond paper including synthetic materials, like polypropylene and polyester, for outdoor and harsh environments.

In addition to the two types of thermal printing processes, printers come in several form factors to fit the needs of your printing level demands. Desktop printers are for the less intense print applications found in offices, schools and small retailers, while industrial printers are the heavy lifters designed for printing thousands of labels daily at high speeds without missing a beat. There are also mobile printers that can integrate with mobile devices (mobile computers, tablets, smart phones) for printing on the move in the field or on the warehouse floor. Whatever your environment and print volume needs are, there is a printer to get the job done.

What Should You Address When Making a Barcode Label Printing System?

When putting together an effective and suitable label printing system there are a few key questions to answer:

- What is the printing volume/duty cycle? Will printing be done on a regular basis or as limited batches?

- What is being labeled? How long does the label need to last?

- Will printing be done at a fixed station or within a mobile environment?

- What are the environmental conditions the label will come across? Indoor/Outdoor, extreme temperatures, exposure to liquids, heavy handling, etc…

- What will the maximum and minimum label sizes be?

- What will be printed on the label? Barcodes, text, images, etc…?

- Will the information on the labels be static or dynamic?

What are the Components of a Barcode Label Printing System?

All label printing systems consist of three core components:

- Barcode Printer – The printer is the center of any system and making sure the unit with the correct

features is used is critical. Choosing the right printer ultimately comes down to how much you will need

to print and the need to be mobile or fixed. Options for interfaces, rewinders, peelers, cutters and

embedded fonts ensure the best configuration is used for your application. - Labels and Ribbon – Media comes is available in a variety of sizes and types for use in any type of

environment. Likewise, labels and ribbon are matched to your printer model to ensure the best print

quality with minimal set-up. - Barcode Software – With the printer and supplies chosen, you still need a means to tell the printer

what exactly to make. Label design software can be as simple as manually creating static or serialized

designs to fully automated print servers dynamically pulling information from a database.